Navdurga Engineers specializes in manufacturing high-quality Rock and Roll Rotomoulding Machines in both Closed Oven and Open Flame configurations. With our extensive experience since 2015, we provide the most economical and efficient solutions for plastic water tank manufacturing and hollow product production.

Most economical start-up option in rotomoulding machinery

Minimal fuel and power consumption with high efficiency

Compact design requiring minimal factory space

Produce tanks from 100L to massive 40,000L capacity

Capable of double & triple layer tanks up to six layers

Only 1 operator + 2 unskilled laborers required

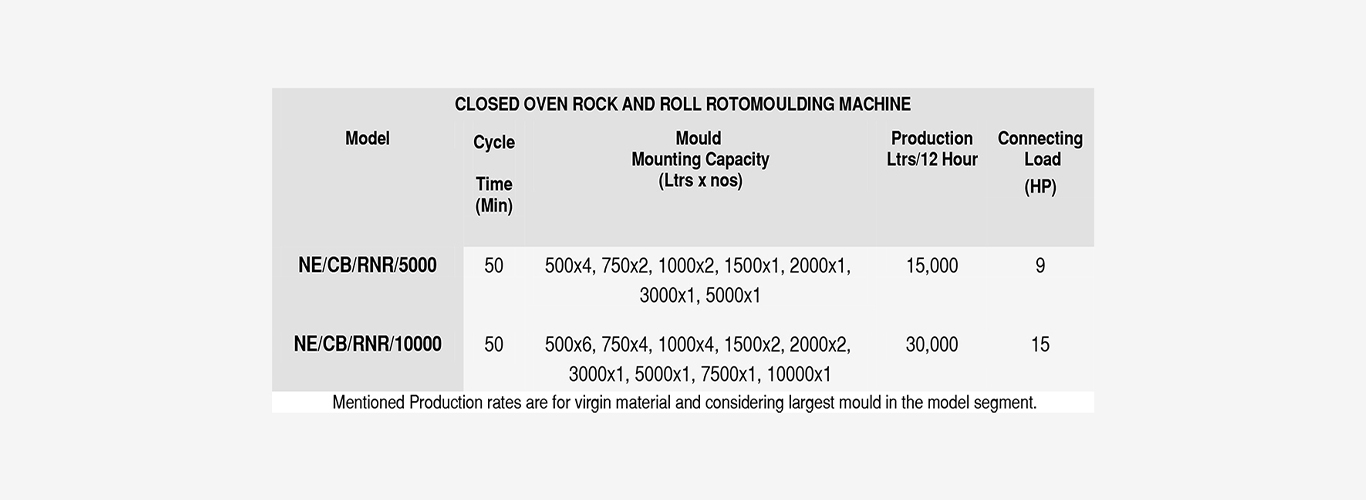

We started manufacturing Closed Oven rock and roll rotomoulding machines since 2015. These machines are specifically designed for producing plastic water tanks and other hollow articles. Our company developed this machine as an economical selection for the current market, offering exceptional value in terms of investment, production cost, and operational efficiency.

The rotomoulding process ensures products with very long lifespan. Compared to other rotomoulding machines like four/three arm bi-axial rotomoulding machines or open flame rock and roll machines, our closed oven version offers significant advantages in production cost, power consumption, production rate, operational costs, and maintenance expenses.

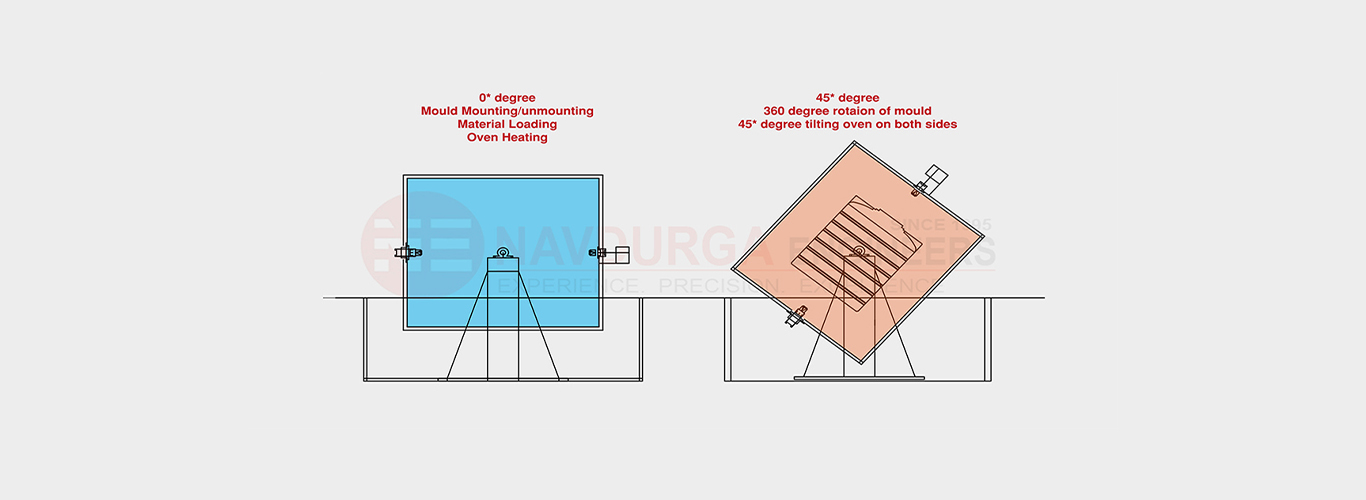

In the entire process, plastic material in powder form is placed into a hollow mould, typically fabricated from mild steel or stainless steel. The mould is closed and fitted inside the oven box. The mould is then heated in an oven whilst rotating 360 degrees horizontally, with the entire oven box tilting at 45 degrees on both sides during the cycle. This continues until the polymer gradually melts and lays-up on the inside of the mould. Once fully melted, the mould moves to a cooling station and is cooled with air or fine water mist. When sufficiently cooled, the product is removed and the process repeats.

In the rotomoulding category, the Open Flame Rock and Roll machine represents the most economical start-up option. This robust machine can produce water tanks up to 40,000 liters capacity, making it ideal for large-scale production requirements.

Specifically suitable for manufacturing giant-sized water tanks and various hollow plastic products requiring large capacity production capabilities.

500 to 5000 liters capacity (NE/RM/RR/5000)

500 to 25000 liters capacity (NE/RM/RR/25000)

Our rock and roll machines require minimal space compared to other rotomoulding machines, typically 200-500 sq ft depending on capacity.

We offer machines from 100L to 40,000L capacity for both closed oven and open flame models.

We provide comprehensive after-sales support including installation, training, and maintenance services across India.

Yes, our machines can produce double, triple, and up to six-layer tanks with uniform material distribution.