Leading Manufacturers in Ahmedabad, Gujarat - ISO 9001:2015 Certified

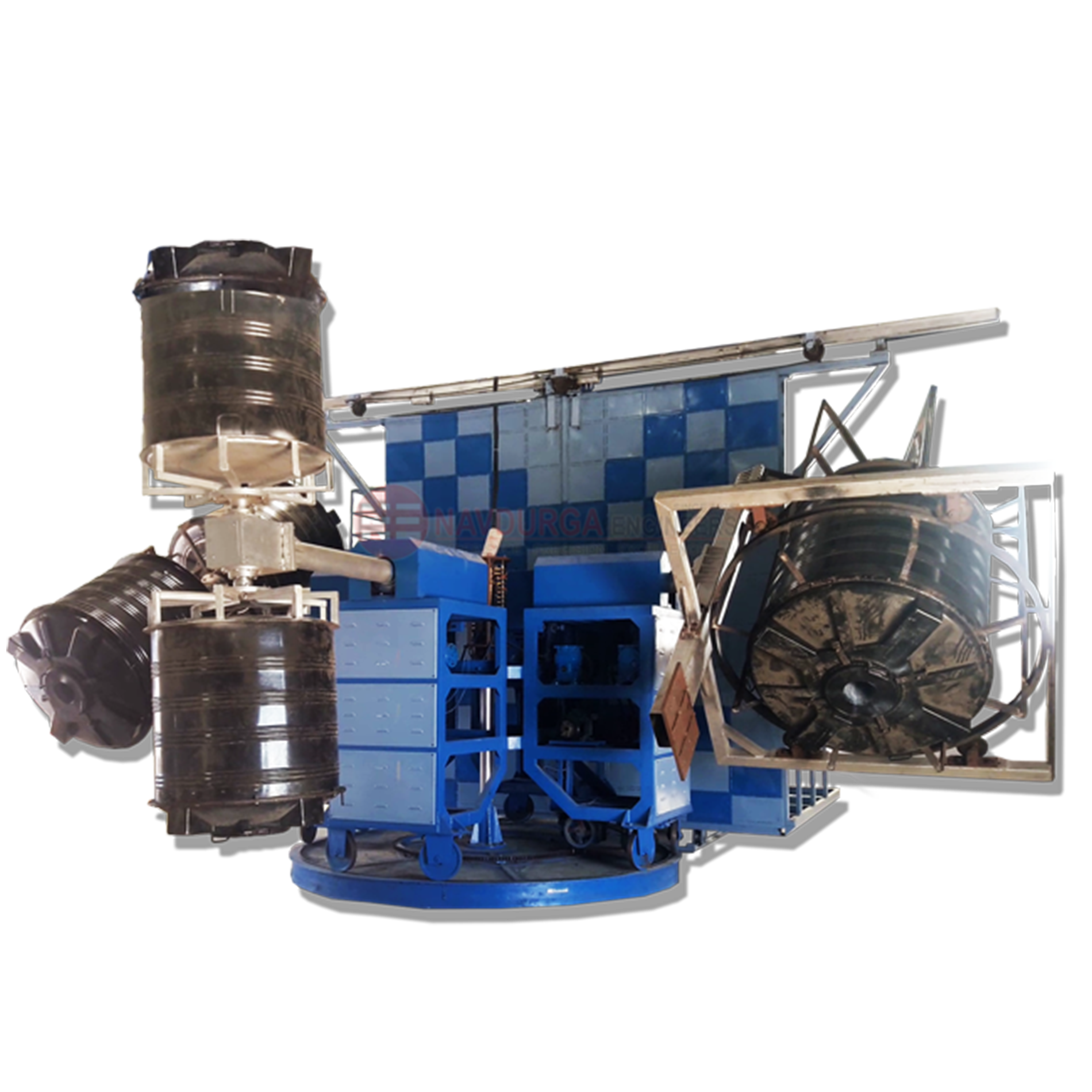

Rotomoulding, also known as rotational moulding, is a plastics moulding technology which is ideal for making hollow articles like water tanks, containers, and industrial products. It is a casting technique but unlike most other plastics processes there is no pressure involved. As leading rotational moulding machine manufacturers in Ahmedabad, we provide high-quality equipment for efficient plastic tank production.

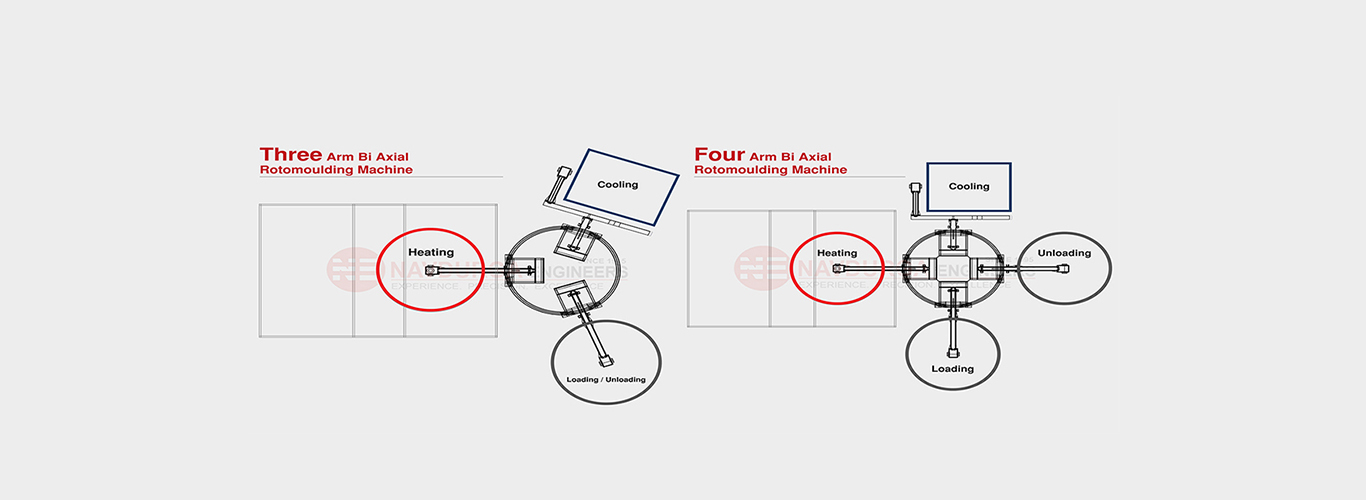

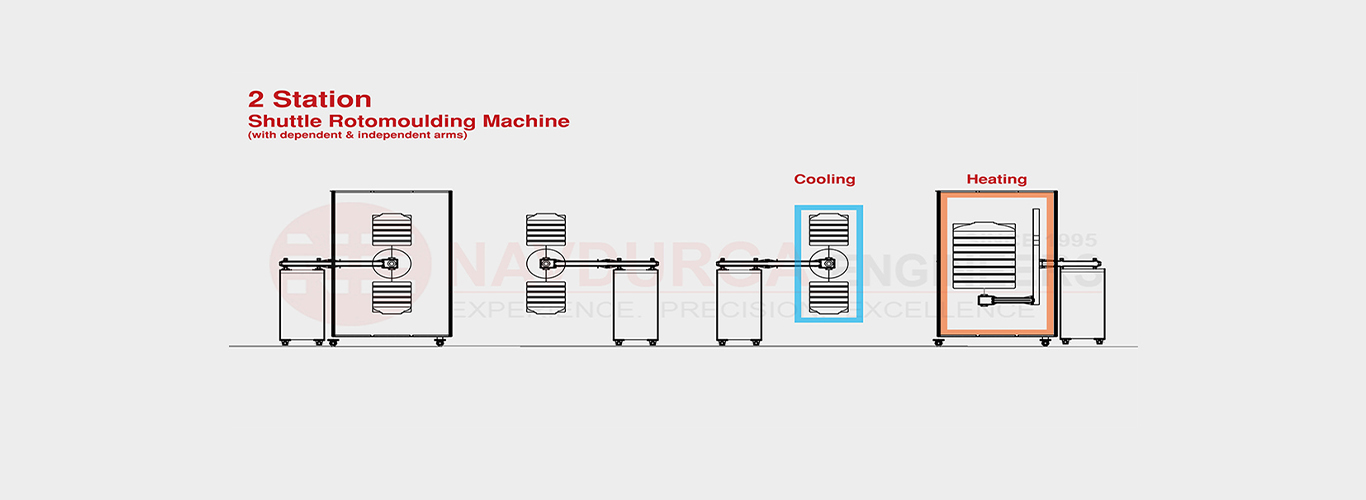

In the entire process, a plastic material, normally in powder form is placed into a hollow mould, usually made from fabricated mild steel or stainless steel. The mould is closed and rotated on arms. The mould is then heated in an oven whilst rotating and the polymer gradually melts and 'lays-up' on the inside of the mould. Once the polymer powder has fully melted the mould is moved to a cooling station and cooled usually with air and sometimes a fine mist of water. As the mould cools the part solidifies. When the material has finally cooled sufficiently to release away from the mould surface. Arm moves to the unloading spot and the product is taken out of the mould & then again reloaded for the next cyclic process.

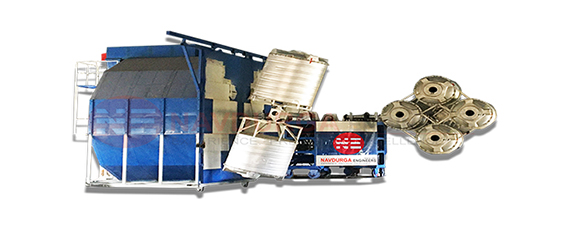

Meanwhile in four arm bi-axial rotomoulding machine, cycle runs constantly. If one arm is in the oven for heating, second arm will be on the cooling station, third arm will be on the unloading spot and forth will be on loading spot. Graphically explained in the layout below.

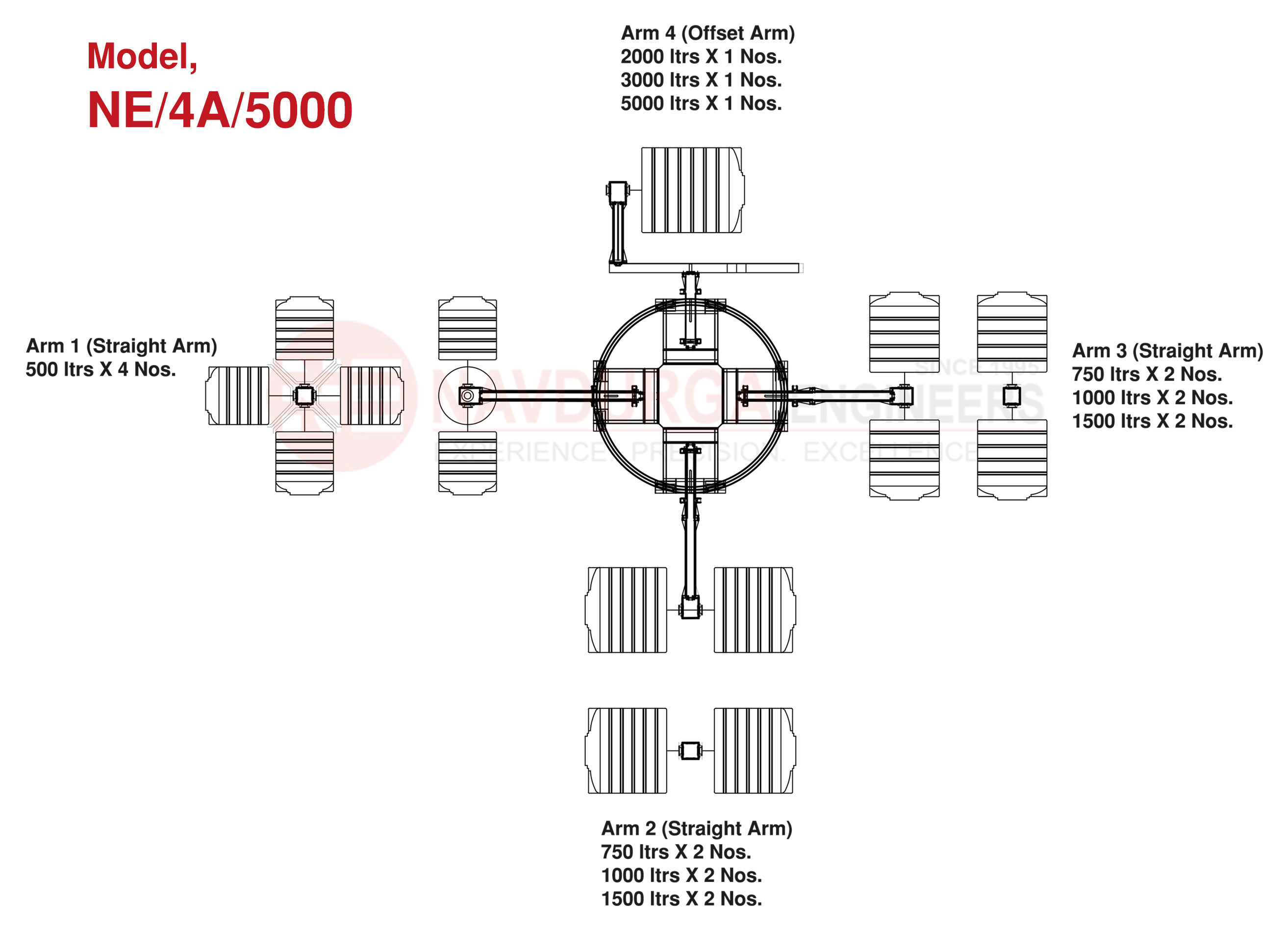

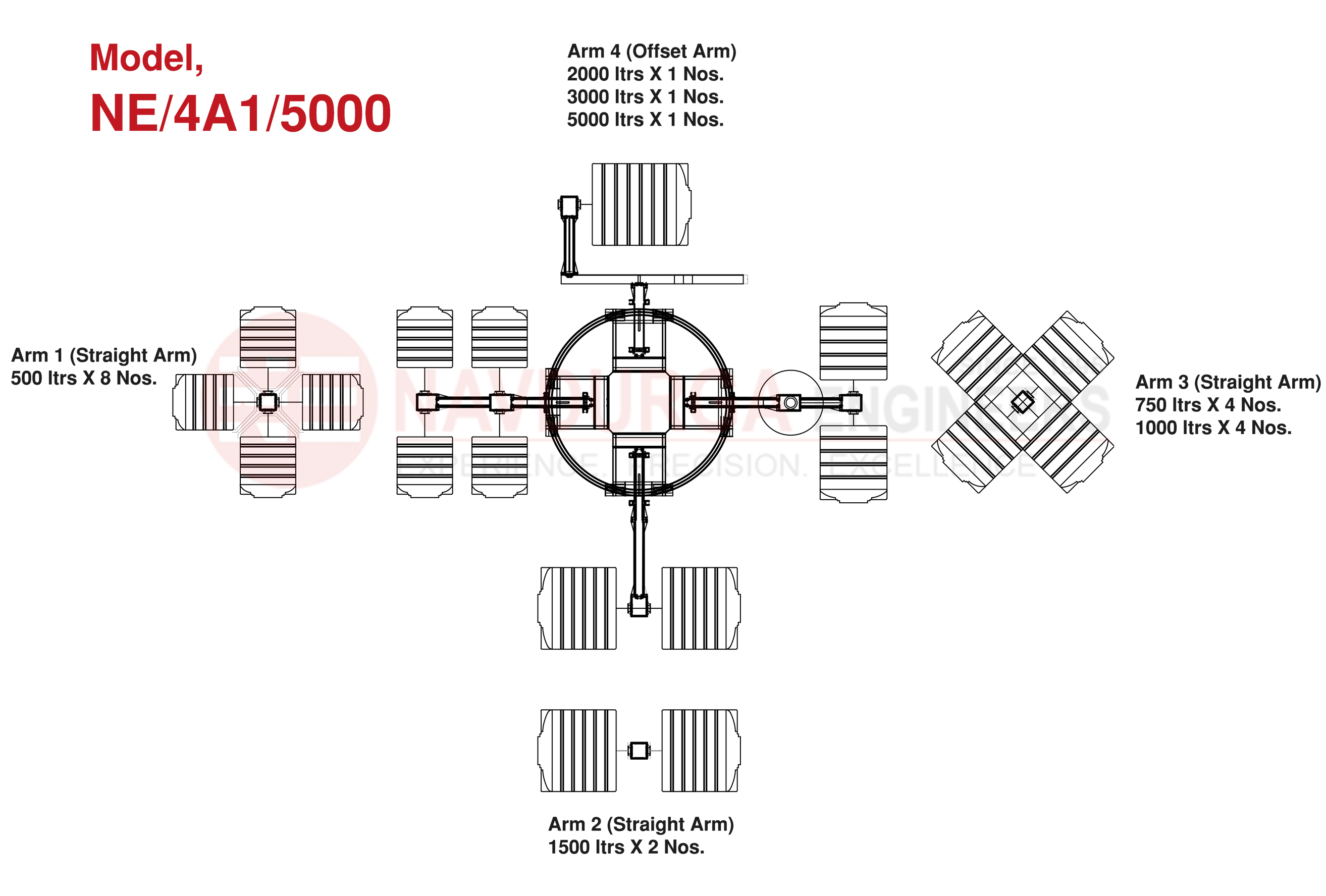

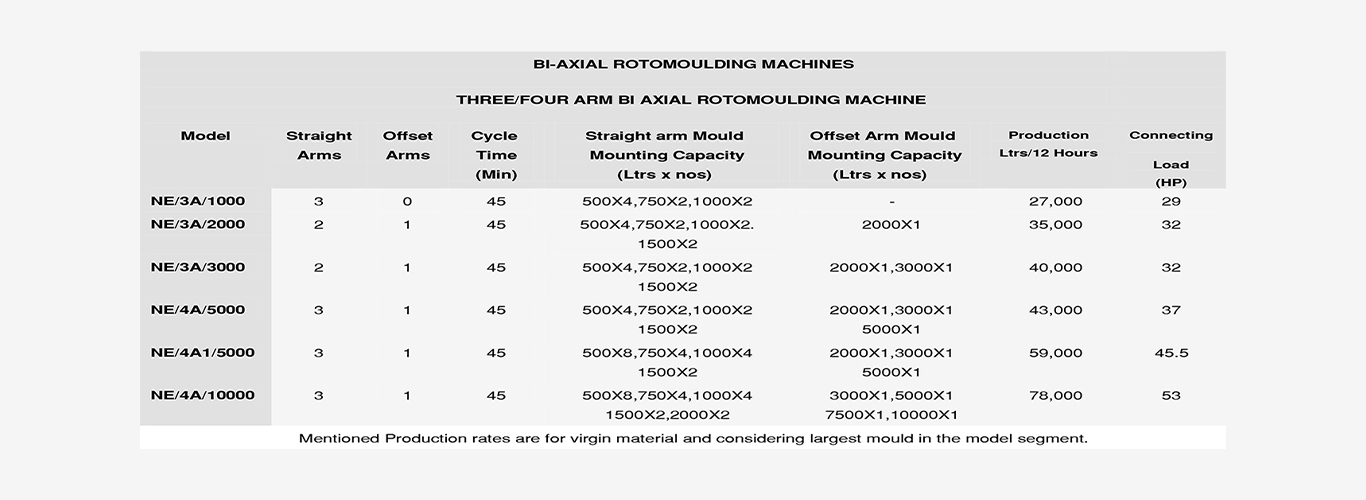

Various Models Available, which are classified according production rates and mould mounting capacity. As leading rotational moulding machine manufacturers in Gujarat, we offer:

These machine models are customizable, where client can choose amount of arms (max 4) and mould mounting options according their requirements.

Maximum Production Capacity Upto 10,000 liters in a single cycle. Perfect for large-scale water tank manufacturing operations.

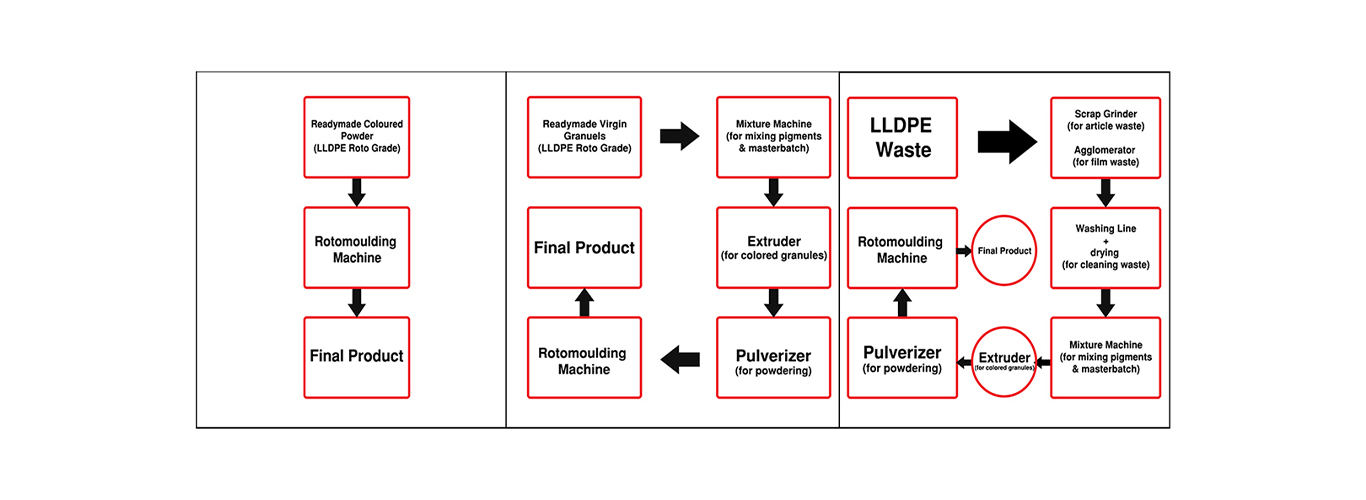

Entire rotomoulding project available Machineries which can convert plastic waste into plastic water tank or any hollow article. List of machineries are as mentioned below:

Contact us for best prices on rotational moulding machines

Call: +91 98795 41422 WhatsApp Now

Navdurga Engineers

📍 Ahmedabad, Gujarat

📞 +91 98795 41422

📧 info@rotomouldingmachine.com

Request Quote